Connector Type

Fiber Type

width

Product Features

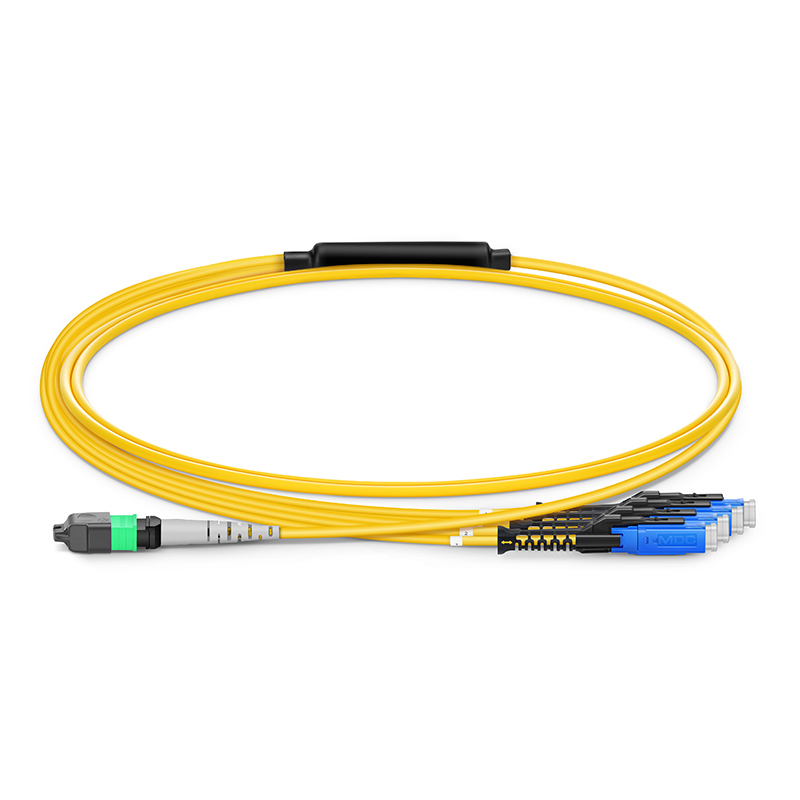

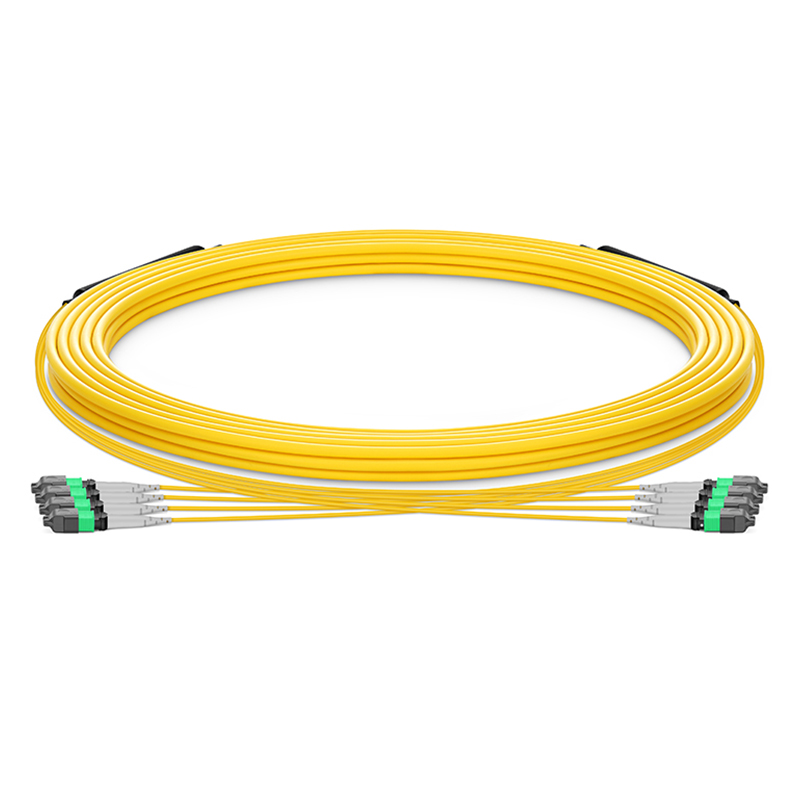

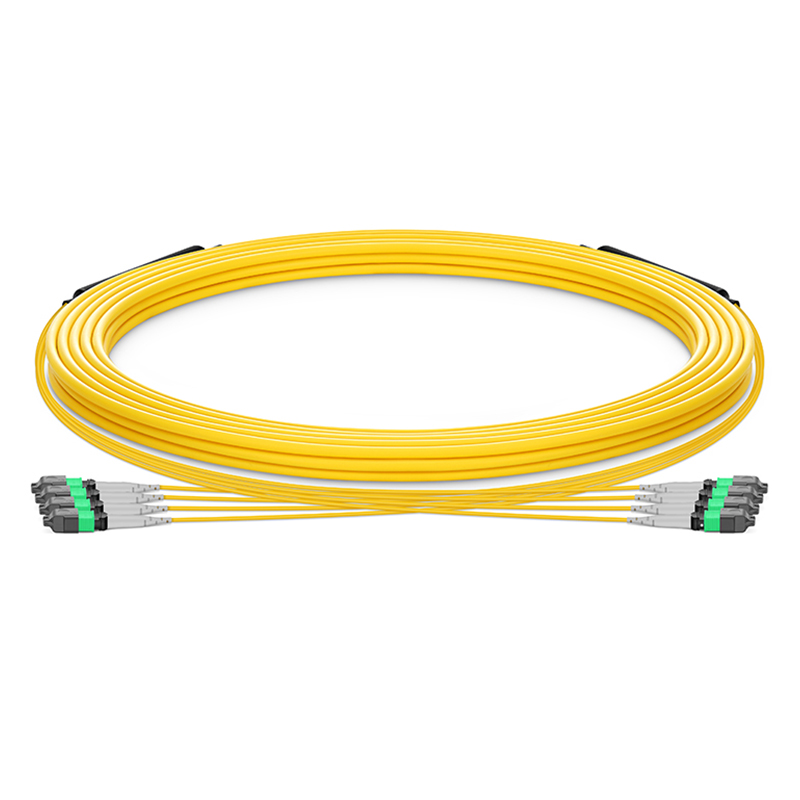

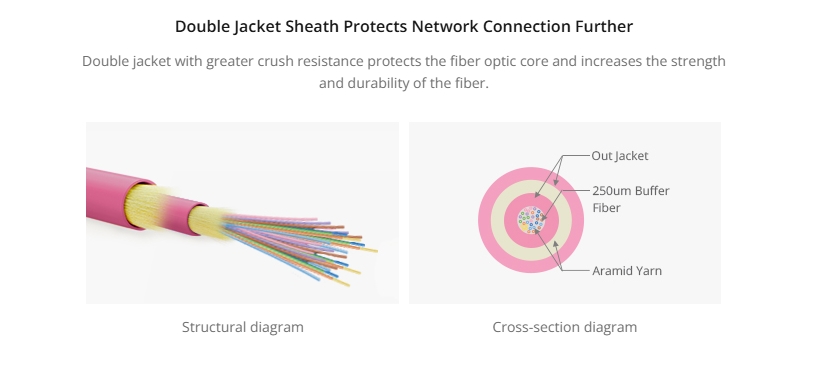

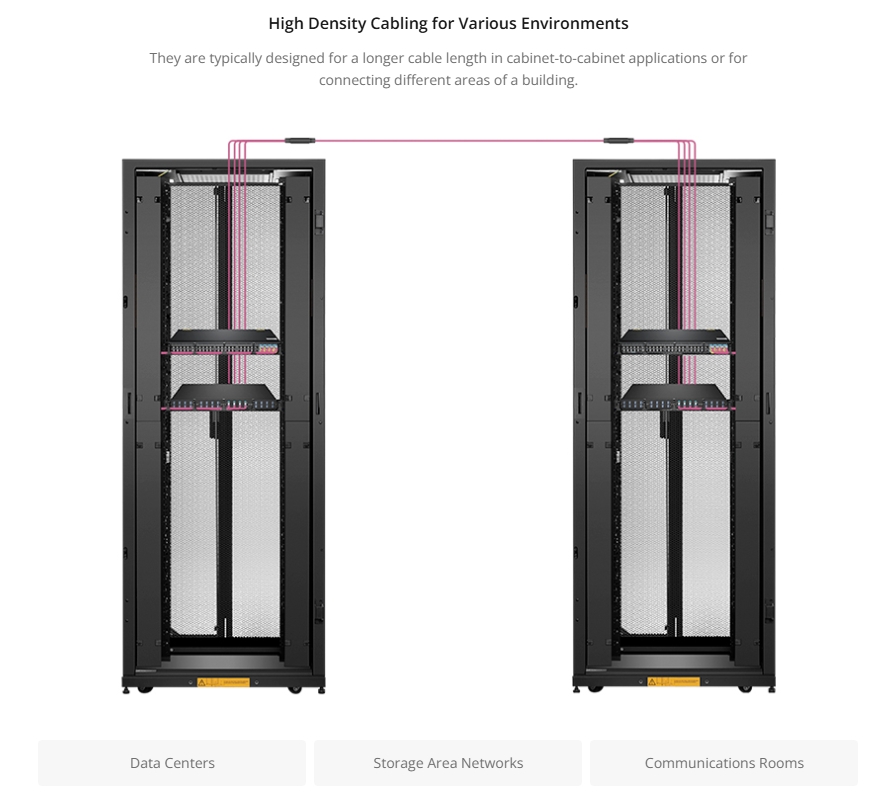

MTP® trunk cables with a more robust double jacket sheath provide greater crush resistance. They are typically designed for a longer cable length in cabinet-to-cabinet applications or for connecting different areas of a building. MTP® cable, a cost-effective alternative to time-consuming field termination, is designed for high-density fiber patching in data centers which need space saving and reduce cable management problems.

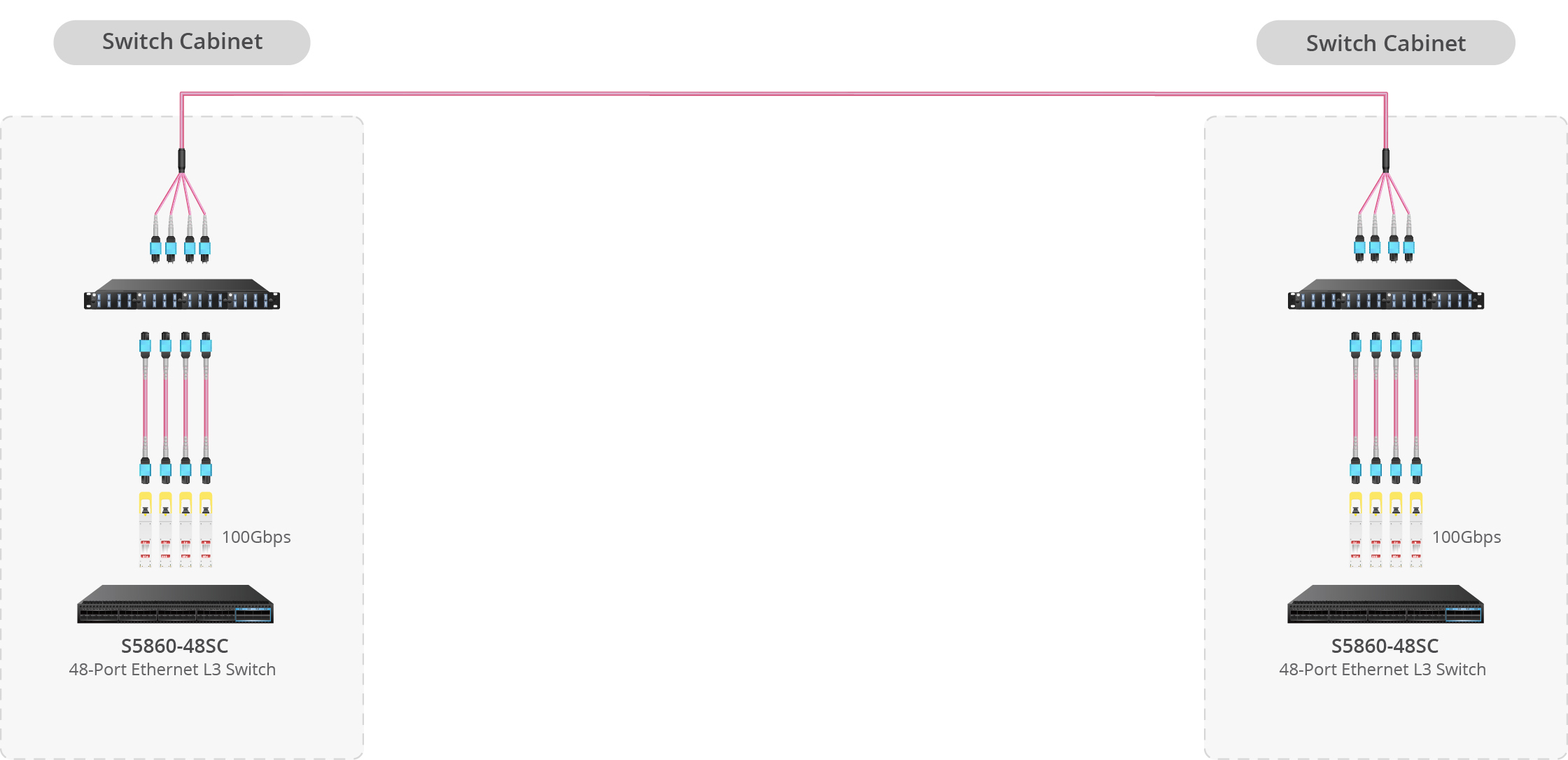

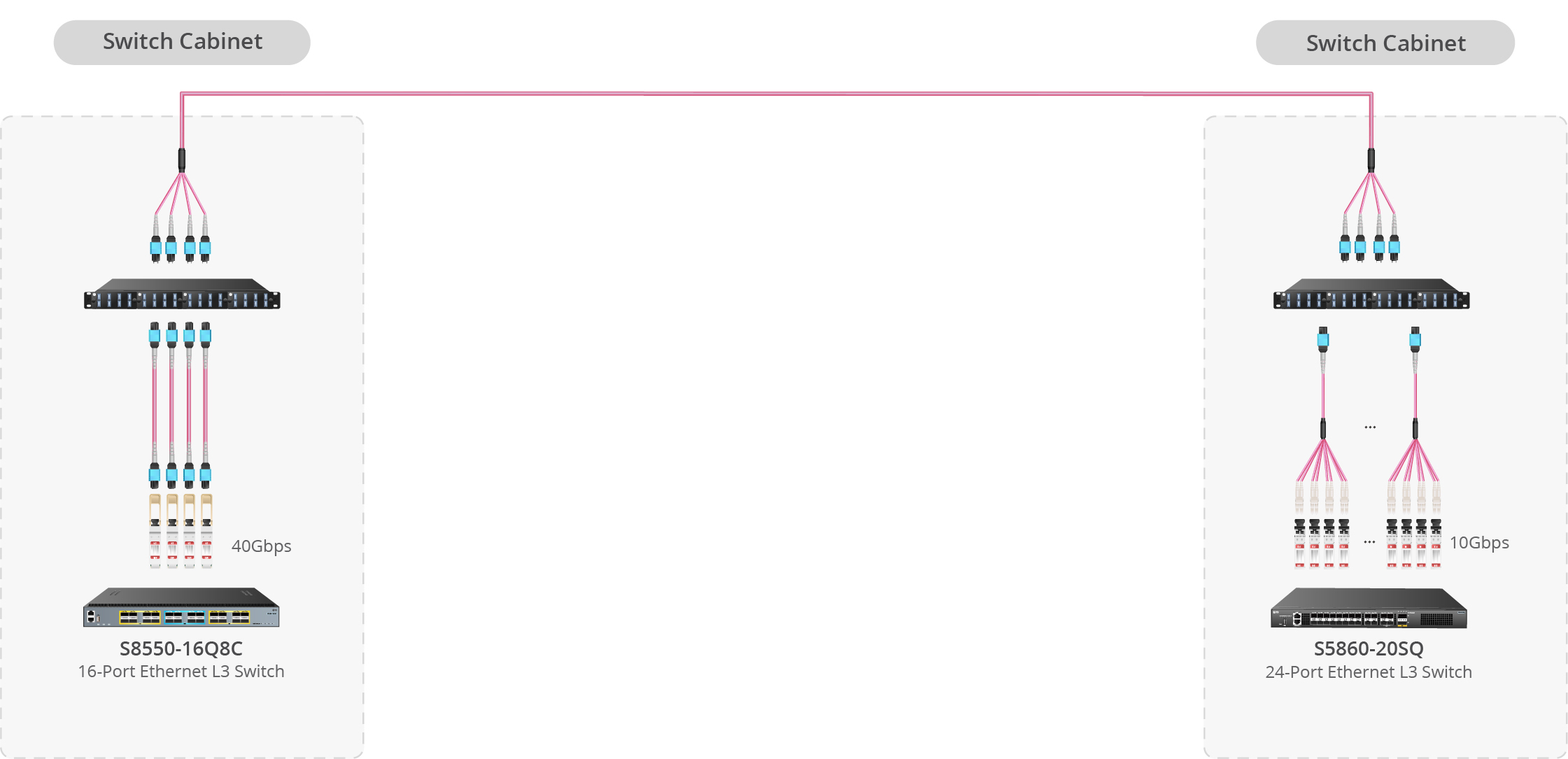

MTP®-8 is ideal for 8-fiber parallel multimode optical transceiver applications, such as 40G QSFP+ SR4/CSR4, 100G QSFP28 SR4 optics connection.

Please note: The US Conec MTP® connectors are fully compliant with the MPO standards, which offer novel patented features, enhanced precision, proven reliability, and significant performance improvements compared to generic MPO connectors.

Specification

| Connector A |

US Conec MTP® Male Elite (Pinned)

|

Connector B |

US Conec MTP® Female Elite (Pinless)

|

| Fiber Mode | OM4 50/125μm | Wavelength |

850/1300nm

|

| Glass Fiber |

Corning ClearCurve® Multimode Fiber

|

RoHS Compliancy Status | Compliant |

| Polish Type | UPC to UPC | Minimum Bend Radius | 7.5mm |

| Insertion Loss | 0.25dB Max | Return Loss | ≥20dB |

| Attenuation at 850nm | ≤3.5dB/km | Attenuation at 1300nm | ≤1.5dB/km |

| Cable Jacket | Plenum (OFNP) | Fiber Count | 8 Fibers |

| Cable Outside Diameter (OD) | 5.5-5.6mm | Breakout Outside Diameter (OD) | 2.0mm |

| Installation Tensile Load | 66N | Cable Structure | 600N |

|

Long-term Tensile Load

|

200N | Cable Structure | Double Jacket |

| Operating Temperature | -10 to +60°C (32 to 140℉) | Storage Temperature | -10 to +70°C (14 to 158℉) |

Quality Testing

Quality Certification

FeatureOverview

Contact Us